| Model | Maximum Capacity | Maximum Allowable/ Operating Pressure |

Body Material | Connection Type | Connection Sizes |

| JD8 | 302,000 lb/hr (136,987 kg/hr) |

300 psig @ 650°F (21 bar @ 343°C) |

ASTM A395 Ductile Iron |

NPT, BPST, Flanged |

2″ (50 mm) |

| KD8 | 300 psig @ 650°F (21 bar @ 343°C) |

ASTM A395 Ductile Iron |

NPT, BPST, Flanged |

2″ (50 mm) 2-1/2″ (65 mm) 3″ (80 mm) |

|

| KD10 | 300 psig @ 650°F (21 bar @ 343°C) |

ASTM A395 Ductile Iron |

NPT, BPST, Flanged |

2″ (50 mm) 2-1/2″ (65 mm) 3″ (80 mm) |

|

| KD12 | 300 psig @ 650°F (21 bar @ 343°C) |

ASTM A395 Ductile Iron |

NPT, BPST, Flanged |

2″ (50 mm) 2-1/2″ (65 mm) 3″ (80 mm) |

|

| L8 | 700,000 lb/hr (317,520 kg/hr) |

250 psig @ 450°F (17 bar @ 232°C) |

ASTM A48 Class 31 Cast Iron |

NPT, BPST, Screwed, Flanged |

2″ (50 mm) 2-1/2″ (65 mm) |

| L10 | 250 psig @ 450°F (17 bar @ 232°C) |

ASTM A48 Class 31 Cast Iron |

NPT, BPST, Flanged |

2″ (50 mm) 2-1/2″ (65 mm) |

|

| M12 | 250 psig @ 450°F (17 bar @ 232°C) |

ASTM A48 Class 31 Cast Iron |

NPT, BPST, Flanged |

3″ (80 mm) | |

| LS8 | 700,000 lb/hr (317,520 kg/hr) |

450 psig @ 650°F (31 bar @ 338°C) |

ASTM A216 WCB Cast Steel |

NPT, BPST, Screwed, Socketwelded, Flanged |

2″ (50 mm) 2-1/2″ (65 mm) |

| LS10 | 450 psig @ 650°F (31 bar @ 338°C) |

ASTM A216 WCB Cast Steel |

NPT, BPST, Socketwelded, Flanged |

2″ (50 mm) 2-1/2″ (65 mm) |

|

| MS12 | 450 psig @ 650°F (31 bar @ 338°C) |

ASTM A216 WCB Cast Steel |

NPT, BPST, Socketwelded, Flanged |

3″ (80 mm) |

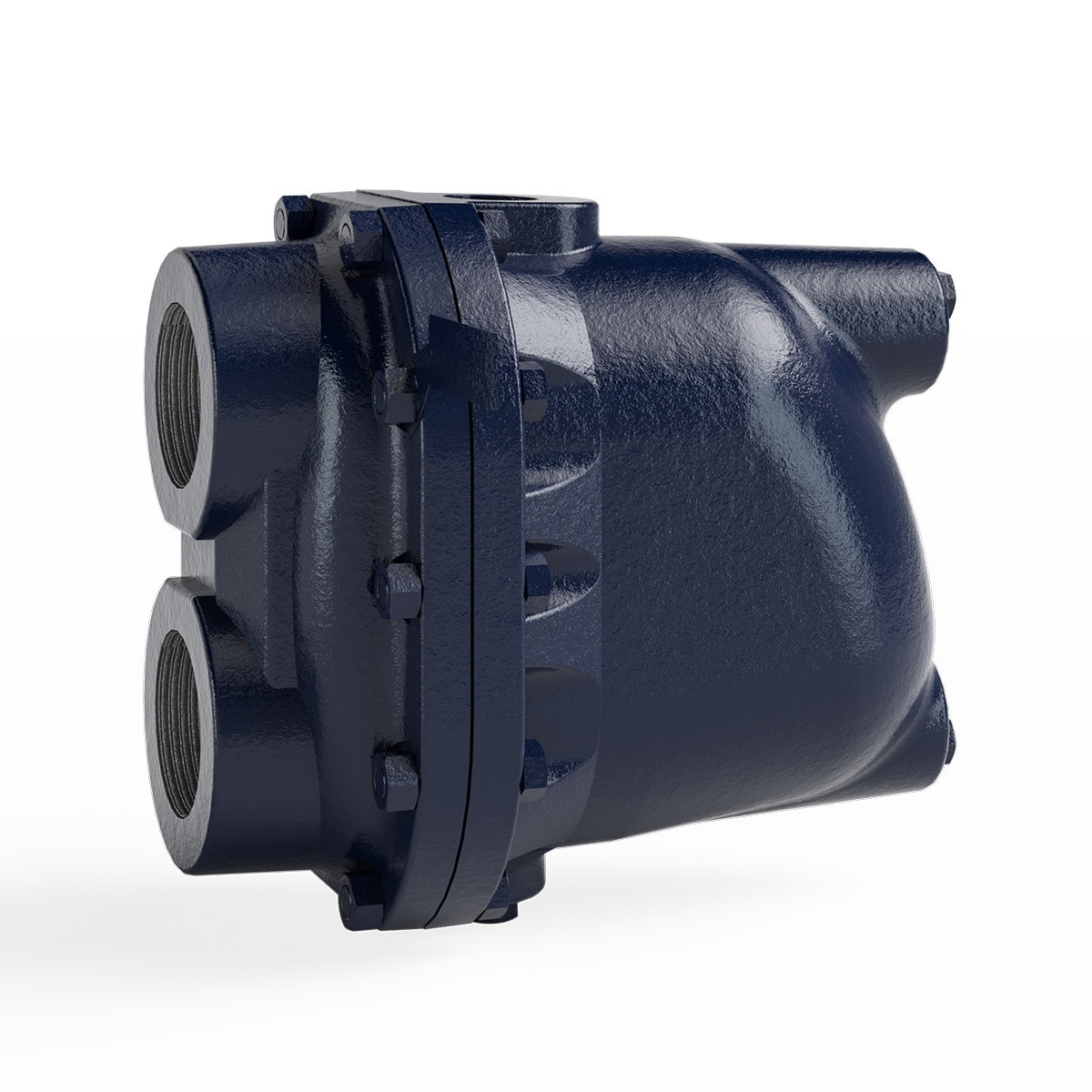

Armstrong Models JD, KD, L/LS, and M/MS ultra-capacity ball float drain traps are designed to meet exceptionally large capacity needs in draining water and other liquids from air or other gases under pressure.

Model L/LS and Model M/MS Series drain traps are available with armored gauge glass with a maximum allowable pressure of 250 psig @425°F (17 bar @ 218°C). When ordering, be sure to specify “Liquid Drainer” or “LD.” Example, LS-series LD, 2” (50 mm) NPT, 7/8” orifice.