Armstrong International’s complete, custom solutions in hot water, steam and humidification are better for your patients and better for you.

Armstrong offers effective steam trapping and condensate removal, automatic steam quality monitoring and precisely controlled humidification, as well as instantaneous and semi-instantaneous hot water generation, digital water temperature control, and a total, end-to-end domestic hot water system solution engineered specifically for the healthcare industry.

Armstrong’s products, systems, services and technology, are designed to help you:

- Provide best-in-class user safety, infection control and compliance, from mechanical room to point of use

- Reduce risks for Legionella, airborne bacteria and hospital-acquired infections (HAI)

- Prevent scalding, wetpacks and static discharge

- Comply with regulations and Standards of Care, such as ASHRAE and World Health Organization

- Fulfill requirements for sterilization and autoclaves, reverse osmosis, dialysis, endoscope reprocessing, cart washing

- Optimize humidity levels and air quality to reduce virus transmission and surface contamination.

- Establish best practices

Reduce Risks for Scalding, Legionella, Airborne Bacteria and Hospital-Acquired Infections (HAI)

Armstrong’s specialists will work with you to address critical issues in mechanical rooms, plumbing systems, hot water tanks and heaters—where incubation of Legionella bacteria most commonly occurs. We’re experts in helping you ensure compliance with healthcare industry regulations and Standards of Care, defined as acknowledged applicable laws, standards and guidelines. Standards of Care that provide critical recommendations for establishing and monitoring hot water system temperature control limits include: ASHRAE Guideline 12-2000 and ASHRAE Standard 188-2015.

Our Automatic Steam Quality Monitoring is Faster, More Reliable and More Accurate Than Manual Methods

Steam QM®-1 provides continuous steam quality measurement data trending over time. By automatically detecting the dryness fraction of steam entering autoclaves, Armstrong’s state-of-the-art monitor allows you to maintain the steam quality necessary for proper sterilization, while also helping to prevent instrument pitting and dangerous wet packs that can stop or delay surgery, costing time and money for hospitals and physicians and increasing the risk of infection.

Reducing Static Discharge and Airborne Bacteria

We provide industry-leading design, manufacturing and application of humidification and conditioned steam equipment for healthcare organizations worldwide. Our energy-efficient, cost-effective solutions consistently deliver the clean, reliable, precisely controlled humidification necessary for reducing static discharge and airborne bacteria, which can ultimately lead to fewer infections and increased safety for patients.

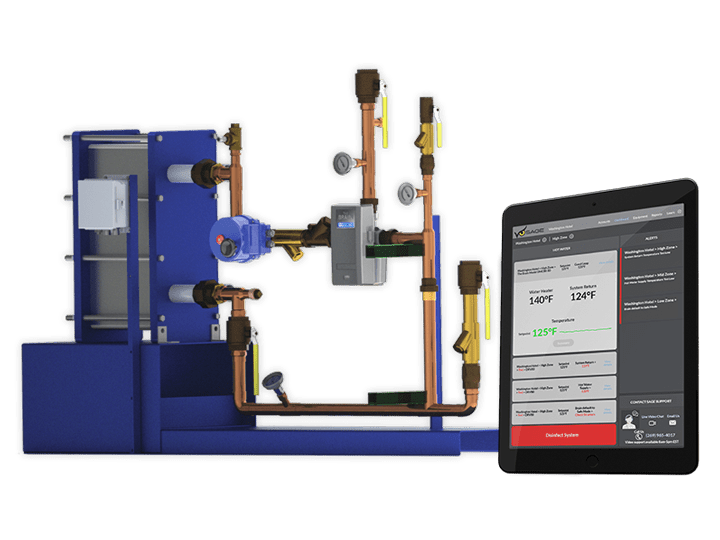

Instantaneous and Semi-Instantaneous Hot Water Generation, Digital Water Temperature Control, and Smart Utility Monitoring, Measuring and Documentation

We provide the hot water system solutions necessary to ensure compliance with Centers for Medicare and Medicaid Services (CMS) requirements and other healthcare regulations and standards of care, which are defined as acknowledged applicable laws, standards and guidelines. ASHRAE Guideline 12-2000 and ASHRAE Standard 188-2015 are Standards of Care which include critical recommendations for establishing and monitoring hot water system temperature control limits.

Complete, On-Site Operation and Maintenance of Your Thermal Utilities

Armstrong’s O&M sites have achieved 99.9+% utility reliability, with 0 recordable instances of safety issues in 2021. Our employees adhere to operational and construction safety guidelines and we comply with all applicable environmental regulations.

Sterilization, Autoclave Applications and Preventing Wetpacks

Armstrong offers a complete array of state-of-the-art products and solutions for your sterilization and autoclave applications, such as: wireless monitoring for steam traps (AIM®), and filtration for clean steam in sanitary applications (ASF steam filters), as well as separators, condensate controllers, PRV stations, and control valves. We can also help you prevent dangerous wet packs, reduce HAI and avoid pitting of instruments by maintaining the proper dryness fraction of steam with our automatic, real-time steam quality monitoring (Steam QM®-1).