Armstrong heat pump packages include rugged, dependable components and state-of-the-art technologies to deliver single- or multiple-circuit versions across the entire performance spectrum.

Armstrong systems are available for plants equipped with one screw or piston compressor for small capacity, such as in the commercial sector, as well as up to three screw compressors appointed for large industrial processes. For high temperature differences between heat sink and heat source, multi-stage systems provide an exceptional solution.

New refrigerants, high temperatures and HFO-ready solutions.

Armstrong has an ongoing commitment to technical and environmental innovation, and to maintaining our proven quality standards throughout product development. As we move forward, widening the performance spectrum for higher media temperatures is an important step, but it presents some challenging requirements. In response, Armstrong offers a wide range of scroll, reciprocating, and screw compressors, embedded with quality components and low GWP refrigerants in packaged system solutions.

Armstrong’s focus is on low GWP solutions.

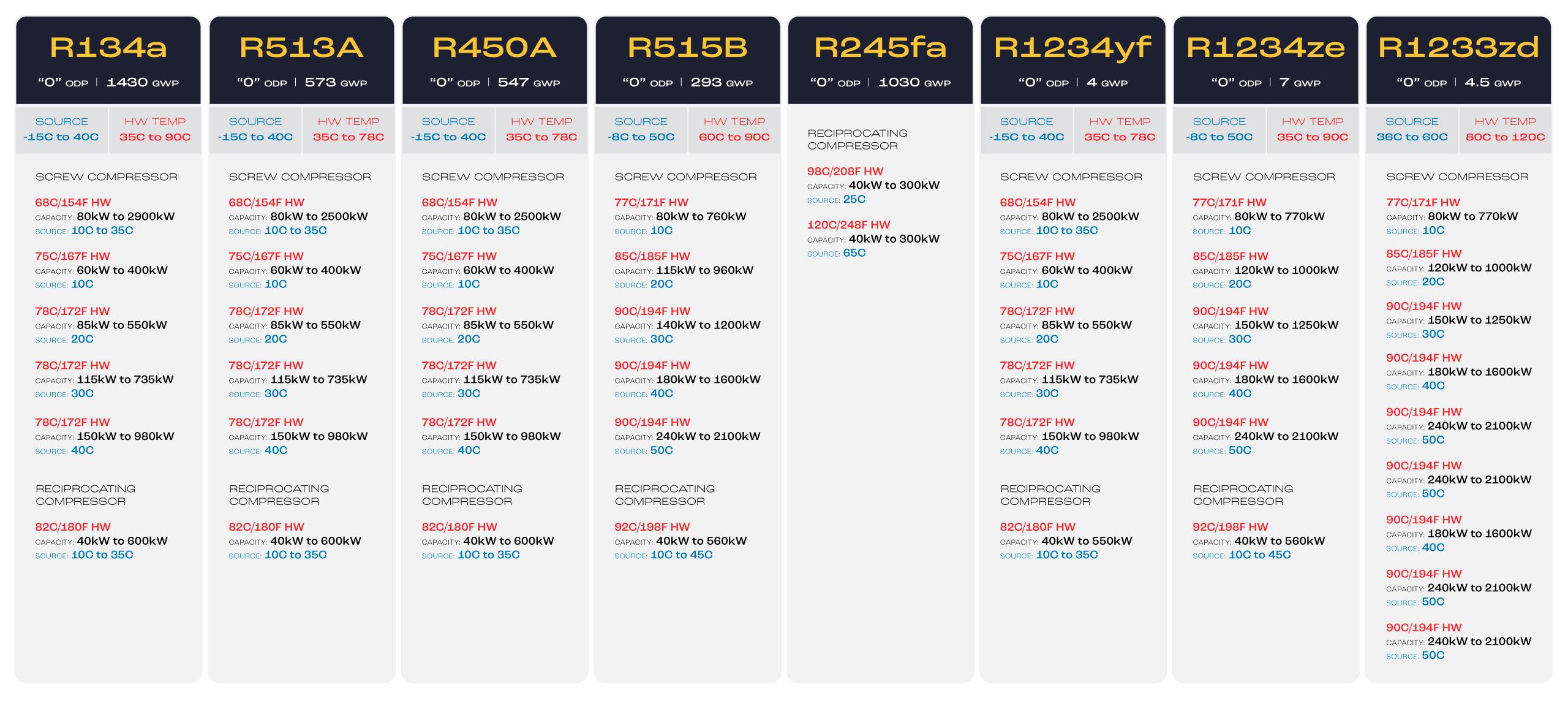

Built to accommodate future standards, our systems are based on low Global Warming Potential (GWP) solutions, including hydrofluorocarbons (HFCs), hydrofluoro-olefins (HFOs), hydrochlorofluoro-olefins (HCFO) and natural refrigerants. The integration of new refrigerants, such as HFOs and HCFO, into our product portfolio is a priority at Armstrong. The extensive temperature range that results allows us to meet the most challenging requirements in the field of heating technology.

A Comprehensive Range of Refrigerants, Temperatures and Applications

Armstrong’s proven R513A / R1234yf / R450A/R134a heat pumps can be employed for a temperature range of up to 82°C (180°F), and we offer a variety of compressors and heat exchanger types that can be adapted to your respective need.

In addition, our R1234ze / R515B heat pumps can be employed for a hot water temperature range up to 92°C (198°F). For highest demand up to 120°C (248°F), the refrigerants R245fa or R1233zd(E) are suitable solutions which combine low-pressure characteristic, environmentally friendly properties, and valuable thermodynamic capability.

R1233zd(E) is the refrigerant of choice for Armstrong industrial high-temperature heat pumps.

Selecting the right refrigerant is a critical decision when designing a heat pump. In addition to being harmless to the environment and people, it should have the thermodynamic characteristics required to produce heat above 80°C (176°F) reliably and economically by running the refrigeration loop at relatively low pressure.

Armstrong and Combitherm have conducted comprehensive technical and economical reviews of refrigerants available for industrial high-temperature heat pump applications. Our conclusion is that only 1233zd(E) delivers the level of safety, reliability and cost necessary for high-temperature heat pumps to be scaled-up sufficiently to have a significant impact on decarbonization of light industries.

Harmless to the environment and people.

The characteristics of R1233zd(E)—which belongs to the HCFO category—make it the refrigerant of choice for industrial high-temperature heat pumps. It has an Ozone Depletion Potential (ODP) of 0, and a Global Warming Potential (GWP) below 5—substantially lower than the GWP > 1000 of most previously used HFC refrigerants.

As a member of the safest A1 Class, R1233zd(E) is nonflammable and nontoxic. It has a very short atmospheric lifetime of 36 days (global average, local values depending on climate conditions) and 0% experimental probability to yield TFA (< 2% theoretical probability). These characteristics explain why R1233zd(E) is increasingly used as a replacement for HFCs in other applications, such as insulation foam sprayed at construction sites, and car air conditioning systems.