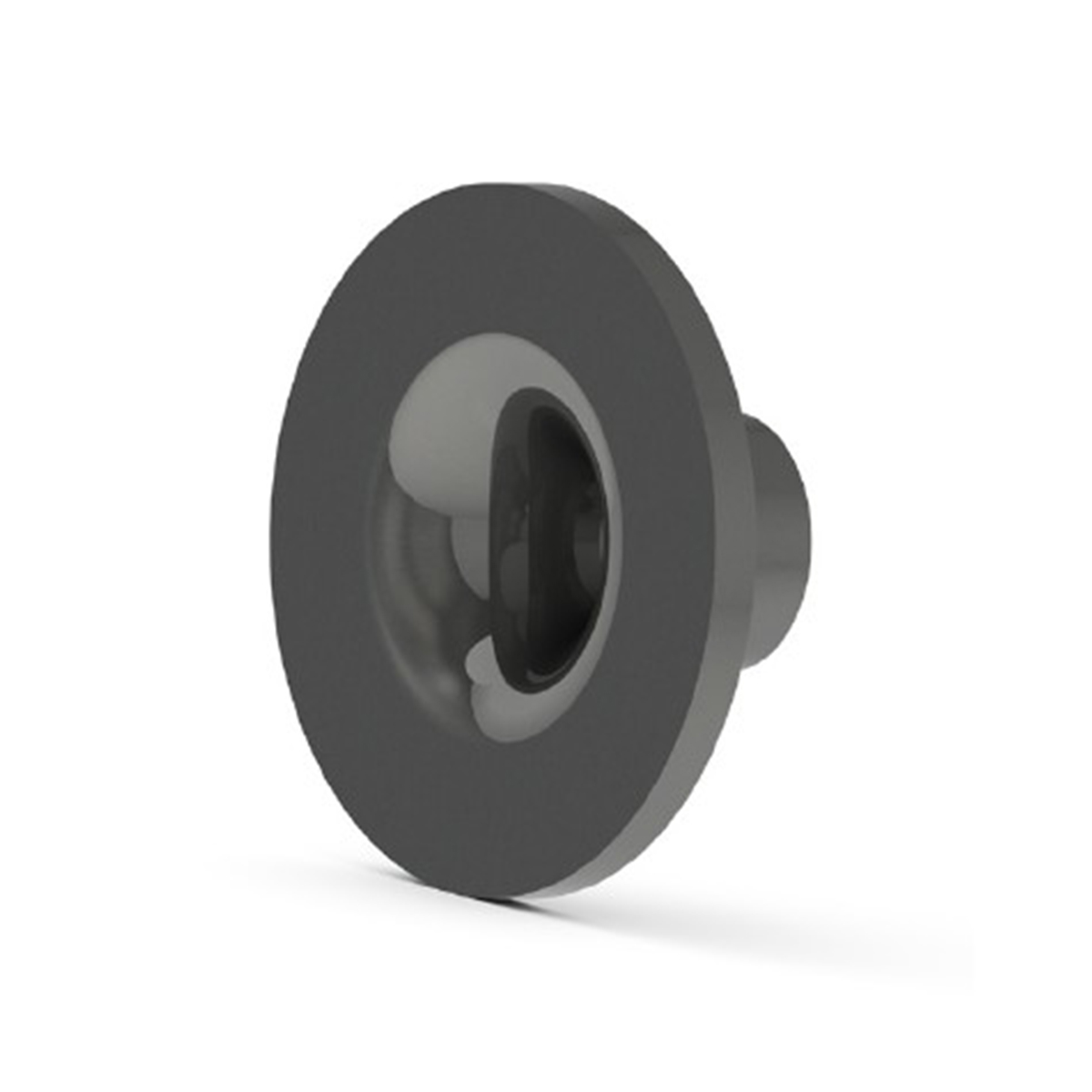

| ANZF | Nozzle Flanged |

| Nozzle designed to be mounted between two flanges. ANZW model available to be welded in between upstream and downstream pipe sections. | |

| ANZFFR | Flanged Nozzle, Flanged Meter Run |

| Flow nozzle machined with a holding flange. The nozzle is mounted concentrically with the process flange of two pipe sections. | |

| ANZWFR | Welded Nozzle, Welded Meter Run |

| Flow nozzle installed within a meter run by welding. Used regularly in high pressure and temperature feedwater and stream applications within power plants where flanged mounting is precluded. |

| AHN | Halmi Nozzle |

| ANZF | Nozzle Flanged |

| ANZFFR | Nozzle Flanged, Flanged, Meter Run |

| ANZFWR | Nozzle Flanged, Welded, Meter Run |

| ANZW | Nozzle Welded-In |

| ANZWFR | Nozzle Welded-In, Flanged, Meter Run |

| ANZWWR | Nozzle Welded-In, Welded, Meter Run |

| APTFFR | PTC-6 Flanged Nozzle, Flanged, Meter Run |

| APTFWR | PTC-6 Flanged Nozzle, Welded, Meter Run |

| APTWFR | PTC-6 Welded Nozzle, Flanged, Meter Run |

| APTWWR | PTC-6 Welded Nozzle, Welded, Meter Run |

The ASME Flow Nozzle is a high performance, reliable measurement device that can be installed in various design and material configurations with conformance to ASME MFC-3M, ASME PTC-6, and ASME PTC 19.5 codes.

The PTC-6 ASME Flow Nozzle provides high accuracy and precision required by ASME PTC-6 in steam turbine testing applications. The assembly consists of a flow conditioner for added accuracy, a diffuser cone for reduced pressure loss, and either a flanged or weld-in flow nozzle.

Available in line sizes 4” to 24” (101.6mm to 609.6mm) with perforated plate or tube bundle flow conditioner, flanged-in or weld-in end connections, and four integrally machined throat pressure taps that are precision-machined and polished.

Design standard ASME PTC-6 or ASME PTC 19.5.